How to Upgrade Your 3D Printer: Modifications for Improved Performance

3D printing technology has come a long way, offering hobbyists and professionals alike the opportunity to create intricate designs and functional prototypes from the comfort of their homes or workplaces. However, even the best 3D printers can benefit from a few strategic upgrades to improve performance. Whether you’re looking to achieve smoother prints, increase efficiency, or expand your machine’s capabilities, several DIY modifications can help you get the most out of your 3D printer.

In the points below, we’ll explore some of the best upgrades you can make, including adding heated beds, upgrading extruders, and improving cooling systems.

Add a Heated Bed for Enhanced Adhesion

One of the most effective modifications you can make to a 3D printer is adding a heated bed. This upgrade can improve print quality by providing better adhesion, especially when working with materials prone to warping, such as ABS and PETG. A heated bed helps maintain a consistent temperature throughout the print, reducing the likelihood of your prints curling at the edges or becoming uneven.

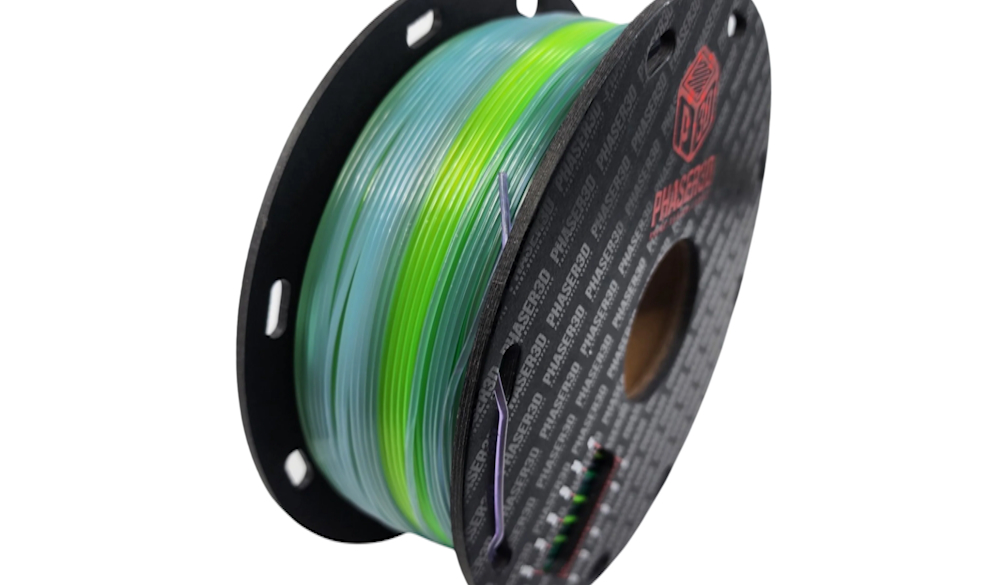

When selecting a heated bed, make sure it is compatible with your printer model and that it can reach the necessary temperatures for the types of filament you frequently use. This modification is particularly useful if you’re working with advanced materials like TPU filament in Australia, as it ensures a smoother, more reliable print.

Upgrade to a Better Extruder for Precision

The extruder plays a vital role in determining the overall quality of your prints. If you’re looking to upgrade your 3D printer for better precision and performance, consider replacing the stock extruder with a higher-quality one. A more advanced extruder can improve filament feed control, minimise clogs, and allow you to work with a broader range of filaments, including flexible materials like TPU.

Direct drive extruders, for instance, offer improved filament handling, especially for flexible and soft filaments. These extruders feed the filament directly into the hot end, allowing for greater control and reducing the chance of tangles or misfeeds. Whether you’re creating intricate designs or functional parts, upgrading your extruder can make a noticeable difference in print quality.

Install Better Cooling Fans for Smoother Prints

Cooling is an essential aspect of 3D printing, as it helps your printed layers solidify quickly, preventing sagging and deformation. Many stock 3D printers come with basic cooling systems that may not be sufficient for complex or high-speed prints. Upgrading your cooling fans can drastically improve the surface finish of your prints and reduce the likelihood of overheating issues.

For best results, consider adding a fan shroud that directs airflow more precisely over the printed part, cooling it evenly. With proper cooling, you’ll notice smoother surfaces, sharper details, and fewer printing errors. This is especially beneficial when printing with filaments that require precision cooling, such as PLA or TPU filament.

Upgrade Your Firmware for Greater Control

If you're looking to unlock the full potential of your 3D printer, upgrading your firmware is a worthwhile investment. Firmware modifications can give you greater control over your machine’s settings, such as temperature regulation, print speeds, and movement accuracy. Popular firmware upgrades like Marlin or Klipper can also offer improved support for advanced features like mesh bed levelling and sensorless homing.

Before upgrading, make sure your printer's hardware is compatible with the firmware you're installing. This DIY upgrade not only enhances performance but also opens the door to more advanced 3D printing techniques.

Consider Auto Bed Levelling for Accuracy

Manually levelling your printer’s bed can be a tedious task, especially if you’re frequently changing print materials or sizes. An auto bed levelling (ABL) sensor is a fantastic upgrade that saves time and improves accuracy by automatically adjusting the bed height during the print. This ensures consistent first-layer adhesion, which is critical for producing high-quality prints.

ABL sensors use a variety of technologies, such as proximity sensors or touch probes, to map the surface of the bed and make real-time adjustments. This upgrade is particularly helpful for beginners who want to avoid the frustration of manual bed levelling or for experienced users looking to increase efficiency.

Upgrade Your Build Surface for Better Prints

The build surface you print on has a significant impact on adhesion and the ease of removing completed prints. Stock 3D printers often come with a basic glass or aluminium bed, which may not be ideal for all filaments. By upgrading to a specialised build surface, such as PEI (polyetherimide) sheets or textured glass, you can improve adhesion and make it easier to remove finished parts without damaging them.

A PEI build surface, for example, works exceptionally well with filaments like TPU, providing excellent adhesion without the need for additional adhesives. Additionally, it’s a durable material that withstands repeated use, making it a valuable long-term investment for your 3D printer.

Upgrading your 3D printer is a rewarding process that allows you to push the boundaries of what your machine can achieve

From adding heated beds and upgrading extruders to installing better cooling fans and firmware, these modifications can significantly improve your printer’s performance and expand its capabilities. Whether you're a hobbyist looking to refine your skills or a professional seeking enhanced precision, these DIY upgrades can take your 3D printing to the next level.